Rapid prototyping - accelerate development with fast prototypes

Rapid prototyping allows ideas to be implemented quickly. Especially in research and development, there seem to be no limits. But what exactly is rapid prototyping? And why is the process particularly advantageous in product development?

In 2004, surgeons in Dallas, Texas, successfully separated two-year-old Egyptian twins who had grown together at the head. The 34-hour operation was a complete success. The complicated procedure was only possible because surgeons were able to plan the complex operation using accurate anatomical models of the twins' skulls and vascular structures of their brains. A large number of these models are made using rapid prototyping. In this process, the boys' skulls were replicated using a 3D printing process with transparent acrylic. This gave the surgeons an unprecedented insight.

The technology, which was considered a sensation at the time, is now, 18 years later, an indispensable part of everyday life in many research and development departments and continues to produce fascinating results.

What exactly is rapid prototyping?

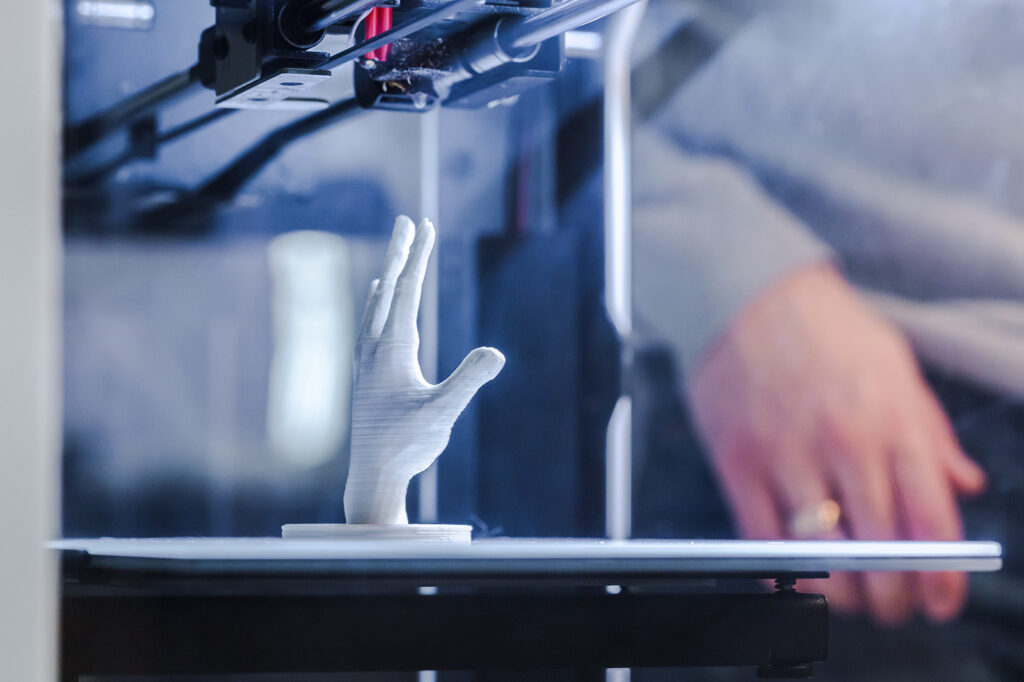

Rapid prototyping refers to a group of manufacturing processes. The processes produce a scalable model of a workpiece or product in a short time using three-dimensional CAD data. In addition to rapid prototyping, the manufacturing processes are also referred to as 3D printing or additive manufacturing processes. Here, a workpiece or product is created by applying materials layer by layer. This is usually done by means of physical or chemical effects in the form of heat or electromagnetic waves.

Probably the best-known process in the field of rapid prototyping is 3D printing using fused deposition modeling (FDM). Here, filamentary plastic, which is also known as filament, is melted by heat in a nozzle and applied layer by layer to the so-called print bed. This form of 3D printing is particularly convincing due to its low cost and speed of implementation. It is therefore well suited for use in the early stages of development.

Rapid prototyping enables developers and designers in particular to quickly make their ideas tangible. Initial designs and ideas thus not only appear in sketches and simulations, but can also be examined haptically.

Advantages of Rapid Prototyping

- Saving money and time: With 3D printing, there are no manufacturing costs for tools. The devices can get started immediately after a very short setup time. In addition, a wide variety of geometries can be produced with one and the same device.

- Better feedback through physical modelsThe fast prototypes can be examined in much more detail and from all sides haptically. They can also be used for presentation purposes.

- Optimize the product at an early stage: Prototypes are produced at a very early stage of DevelopmentThis means that feedback can be taken into account right from the start of development. The use of the prototypes in tests also provides information about the function.

- Waste reduction: Compared to subtractive manufacturing processes, such as milling or turning, in which material is removed from a raw material, rapid prototyping significantly avoids or reduces scrap material.

Rapid prototyping in product development

Especially in the area of product development, the fast and uncomplicated production of a prototype can be of great advantage. This is because 3D printing significantly reduces the time between a 3D design file and a production-ready product. Developers and product designers gain a comprehensive understanding of the product at an early stage of the project and can optimize the product virtually by gaining real-life experience of using it. Thanks to the quickly available prototypes, several development steps can also be initiated, which also has a very positive effect on the development period. Customers and project partners also gain an early impression of the product and can introduce change requests before high costs arise.

Source: Siamese twins successfully separated thanks to 3D printed model