Refrigerator temperature control with PDF table

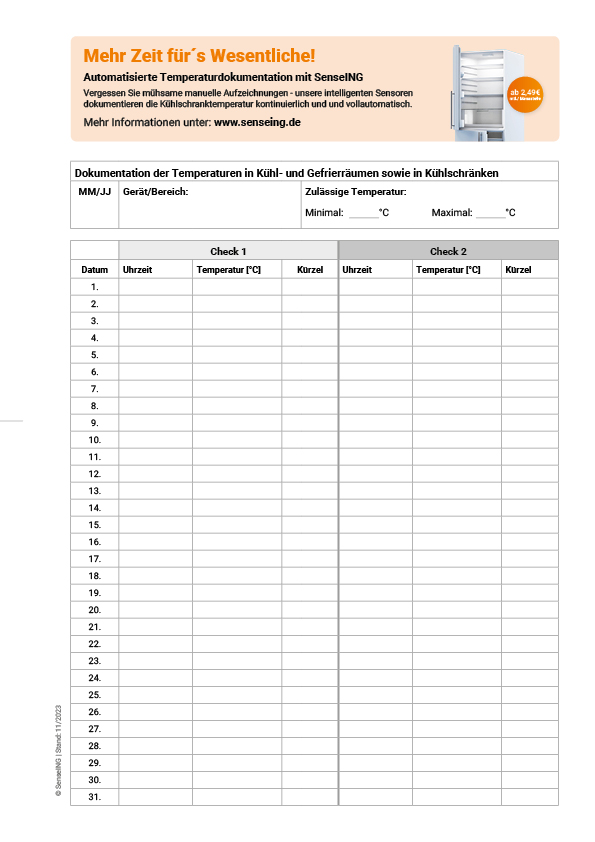

PDF table for manual documentation of the refrigerator temperature

For those who still prefer the traditional method of manual temperature documentation, we offer a PDF table to help you record the refrigerator temperature. This chart provides a clear structure to record temperatures correctly. However, we would like to point out that automated systems with intelligent sensors can save resources and increase accuracy.

The following article explains why a PDF table alone is no longer sufficient and the advantages of automated documentation.

Why manual temperature documentation is not enough and how it works more easily

In a world where technology and innovation go hand in hand, it's time to rethink outdated methods of temperature control in refrigerators. Many organisations still rely on manual documentation with a thermometer and chart on paper to ensure that their food and refrigerated medicines are kept safe. However, this task is often carried out by staff who are already under a heavy workload. The good news is that there is a better and more cost-effective solution: automated documentation using intelligent sensors. This allows staff to concentrate on their core business again, which ultimately saves time, nerves and money.

Why the PDF table is no longer sufficient

Manual refrigerator temperature recording in tables is time-consuming and error-prone. Records can be forgotten, made up or entered incorrectly. This carries the risk of inconsistencies and inaccurate data, which can jeopardise the safety of goods. In addition, manual monitoring can only be done at specific time intervals, which means you may not recognise important temperature fluctuations.

Networked refrigerators for seamless documentation

Networking fridges may seem complex at first glance, but in practice it is surprisingly simple. Thanks to modern technologies, refrigerators can be equipped with intelligent sensors that can be integrated into the appliances with little effort. The system consists of three components: The sensors are simply inserted into the fridge, central receiving stations collect the data and forward it to a cloud application. The simplicity of these systems enables particularly cost-effective integration without costly changes to the infrastructure.

We automate your temperature documentation, you relieve your staff

Find out more about how you can fulfil your documentation obligations in an efficient and automated way!

The advantages of automatic documentation with sensors

In addition to simple and cost-effective integration, systems for automatic temperature documentation in refrigerators offer a number of other advantages.

Continuous monitoring

Sensors enable round-the-clock, continuous monitoring of the refrigerator temperature. This allows temperature curves to be mapped precisely.

Precise data

Minimising the risk of human error during data capture. This contributes to more accurate and reliable data, which is particularly important in environments with strict quality standards.

Time saving

As no manual recording by personnel is required, you save time and resources. You no longer have to deal with tedious documentation.

Alerting

You receive immediate warnings in the event of deviations from the specified temperature limits. This allows you to act quickly to solve potential problems.

Central administration

The recorded data is stored centrally in the cloud, which enables detailed traceability in the event of inspections or quality controls.

Personnel relief

As no manual recording in PDF tables is required, you save time and resources. You no longer have to struggle with tedious documentation.

Conclusion

In a world where time and precision are of the essence, manual refrigerator temperature control with pen and paper is no longer fit for purpose.The use of sensors and automated documentation is not only more efficient, but also safer. When it comes to storing goods that require refrigeration and complying with health regulations, you should rely on modern technology. This allows your staff to concentrate more on their core business, which ultimately saves time, nerves and money.