Automated cold chain monitoring

Permanent cold chain monitoring is indispensable. Especially for temperature-sensitive goods, an unbroken cold chain is of great importance to prevent possible damage or returns. With the sensor systems from SenseING, you ensure the quality of your foodstuffs while automatically fulfilling documentation obligations.

Wherever the monitoring of temperature, humidity and location is important, the sensor systems from SenseING are used. The systems are part of a complete solution for the fully automated acquisition of climate data.

The collected data are stored in an IoT platform and can be accessed at any time to provide evidence. In addition, the data can provide information on debt or liability issues and help optimize the supply chain in the long term.

Wherever the monitoring of temperature, humidity and location is important, the sensor systems from SenseING are used. The systems are part of a complete solution for the fully automated acquisition of climate data.

The collected data are stored in an IoT platform and can be accessed at any time to provide evidence. In addition, the data can provide information on debt or liability issues and help optimize the supply chain in the long term.

Reliable monitoring of your transport

Our measuring units, specially developed for monitoring cold chains, can be easily integrated into your existing infrastructure.

Reduce your personnel costs

Our energy-efficient solutions do not require battery changes. This ensures seamless recording of data at all times and allows employees to focus on their core tasks.

Automate the documentation

Fulfill documentation obligations with ease. Our sensor systems collect temperature and climate data and transfer them fully automatically to the IoT platform, where they can then be stored and accessed at any time in clear dashboards.

Minimize complaints

an returns

Early warnings enable those responsible to react to temperature changes in good time and thus prevent damage.

Total solutions from a single source

Hardware

Our total solutions include the three components hardware, software and service. All our sensor systems are a compilation of various sensor, telematics and energy supply modules. To enable automated processes, the systems either offer very long battery runtimes or resort to so-called energy harvesting to use energy from the environment.

Software

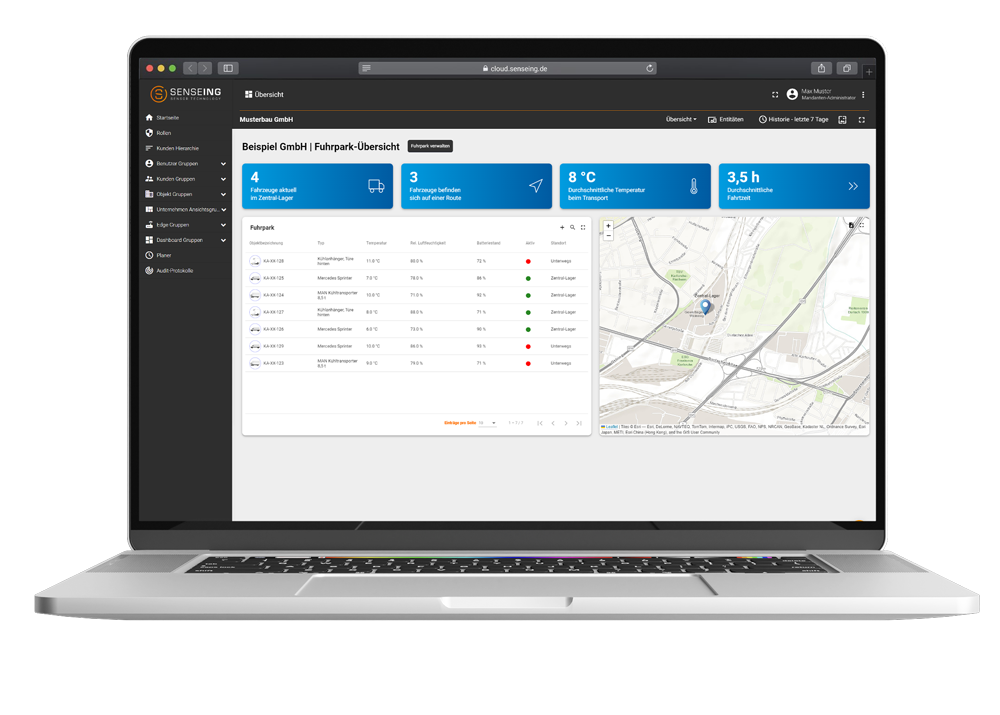

On our IoT platform, we collect telemetry data that was previously collected by the sensor systems. The platform is primarily used to store, manage and visualize the data. Data in the memory can thus be retrieved at any time and as needed.

Service

The highest level of service quality is our top priority. We advise you individually, accompany you during commissioning and configure systems to your needs. In addition, our support provides timely and reliable processing of your inquiries and reporting.

Was unsere Kunden sagen

Sven Weißer, IT

„Die Ideen und die Umsetzung von SenseING begeistern uns immer wieder, einfach und doch effektiv und zuverlässig. Hier passt einfach alles – das Handling, die flexiblen Konfigurationsmöglichkeiten, die kompakten Ausmaße, das schlichte und trotzdem robuste Design, die Zuverlässigkeit und vor allem der überragende Kundensupport.

So geht moderne Temperaturüberwachung von heute.

Das hoch motivierte Team von SenseING hat uns sowohl bei der Auswahl der richtigen Komponenten als auch bei der Einrichtung schnell und unkompliziert weitergeholfen.

Für alle die Ihre Raumklima zuverlässig und einfach überwachen wollen ist unsere Empfehlung eindeutig- Das Team der SenseING GmbH .”

Automated

evaluation

of your data

The transmitted data are collected, stored and processed in a cloud. This allows you to keep an eye on the location of your goods and devices at all times. Even conveniently on the road.

Data Analysis

Events can be characterized and clearly assigned from the measurement data. In this way, it is also possible to make statements about the status or utilization of a device.

Dashboards

Your measurement data is automatically displayed in clear and meaningful dashboards, such as diagrams or maps.

Alerting

Send configurable notifications via email or SMS to multiple users and increase effective communication.

Data storage

All notifications and captured data from your sensors are stored in central databases.

Safety

Our devices communicate exclusively via end-to-end encryption.

Integration

Standardized interfaces allow you to easily integrate the data into your existing system.

Sensors for cold chain monitoring

LoRa Temperatur-Sensor

The träck tracking solution is suitable as a temperature registration device for attachment directly to the goods. The tracker achieves runtimes of up to 4 years.

Energy self-sufficient LoRa temperature sensor

The energy self-sufficient LoRa temperature sensor SLC-PV is suitable for monitoring vehicles and storage areas.

Energy self-sufficient 4G temperature sensor

The SNC-PV temperature sensor is energy self-sufficient thanks to solar panels. The sensor is primarily attached to insulated containers.